The Only Guide for Sheroz Earthworks

The Only Guide for Sheroz Earthworks

Blog Article

Examine This Report on Sheroz Earthworks

Table of Contents3 Easy Facts About Sheroz Earthworks ExplainedSheroz Earthworks Can Be Fun For AnyoneSheroz Earthworks for BeginnersSheroz Earthworks Fundamentals ExplainedThe Buzz on Sheroz Earthworks

For any type of earthwork contractor, it is important to do collaborate with quality, accuracy, and on schedule. Utilizing maker control in work devices enables optimizing the different phases in the earthwork process, from preparing to the upkeep stage - trimble parts. The machine control system aids the machine operator in attaining the target airplane quickly and quickly

The equipment control system overviews the operator with centimeter precision. With Xsite PRO 3D, you'll always recognize precisely just how much to cut or fill. Your neighborhood Xsite technological assistance can direct you and assist with any kind of troubles without seeing the site. Remote support conserves money and time, as it lessens downtime in jobsites.

The Best Strategy To Use For Sheroz Earthworks

Added training and guidelines are always offered over remote support when required. The earthmoving sector has used our field-proven services since the early 1990s. Our system's parts are very carefully made to endure the rough problems of construction sites. Comparison of the same job performed making use of machine control versus the traditional approach discloses that, generally, the conventional method needs 50% even more time to complete the very same task as the technology-assisted approach. https://www.giantbomb.com/profile/sherozau/.

Enter the Xsite device control system; it's below to offer you with a considerable benefit when functioning with earthmoving equipment. Discover how Xsite Equipment Control can enhance your efficiency and ensure job safety and security! Xsite Maker Control systems can be set up to any type of excavator from mini excavators to huge mining excavators.

Exactly how does machine control job? In 2D systems, the device is outfitted with calibrated disposition sensing units.

The system is very simple to learn the basics can be instructed in under one hour of training. Just how does the remote assistance job? A wireless web connection makes it feasible to establish a remote link in between the equipment control system and the solution.

A Biased View of Sheroz Earthworks

What sort of data layouts Xsite systems support? Xsite Maker Control systems sustain open common documents layouts, making it possible for smooth info circulation from one system to one more. Supported file styles: 2D-Maps: DXF Point files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Models: DXF, XML What components are installed on my equipment? Relying on your option of system (with or without placing, i.e - topcon laser levels., 2D or 3D), your machine is geared up with disposition sensing units, a controller device, and a display/operating panel.

Numerous software and hardware options exist to help establish a machine's present position on the earth and contrast it with a wanted layout surfaceand building operators can do more to leverage the benefits. Maker control is making use of different placing sensors and a display screen to give the operator with a recommendation between the placement of the container or blade and the target quality.

Relying on the setup, machine control systems can offer the operator with a basic visual overview to bucket or blade position, or can immediately relocate the blade to quality by speaking with the device's hydraulics - https://papaly.com/categories/share?id=2fb5cd080ed44e92a364571e3aef5522. There are machine control systems readily available for almost any type of equipment: graders, dozers, excavators, soil and asphalt compactors, scrapers, leaners, milling equipments, and pavers

The Basic Principles Of Sheroz Earthworks

Some benefits consist of lowered rework, boosted task efficiency, and lower evaluating costs. Machine control can also assist boost efficiency and lower total prices. This technology is altering the means the building market functions. Building and construction devices without device control will certainly end up being a distant memory and the advantages obtained from it will certainly be numerous.

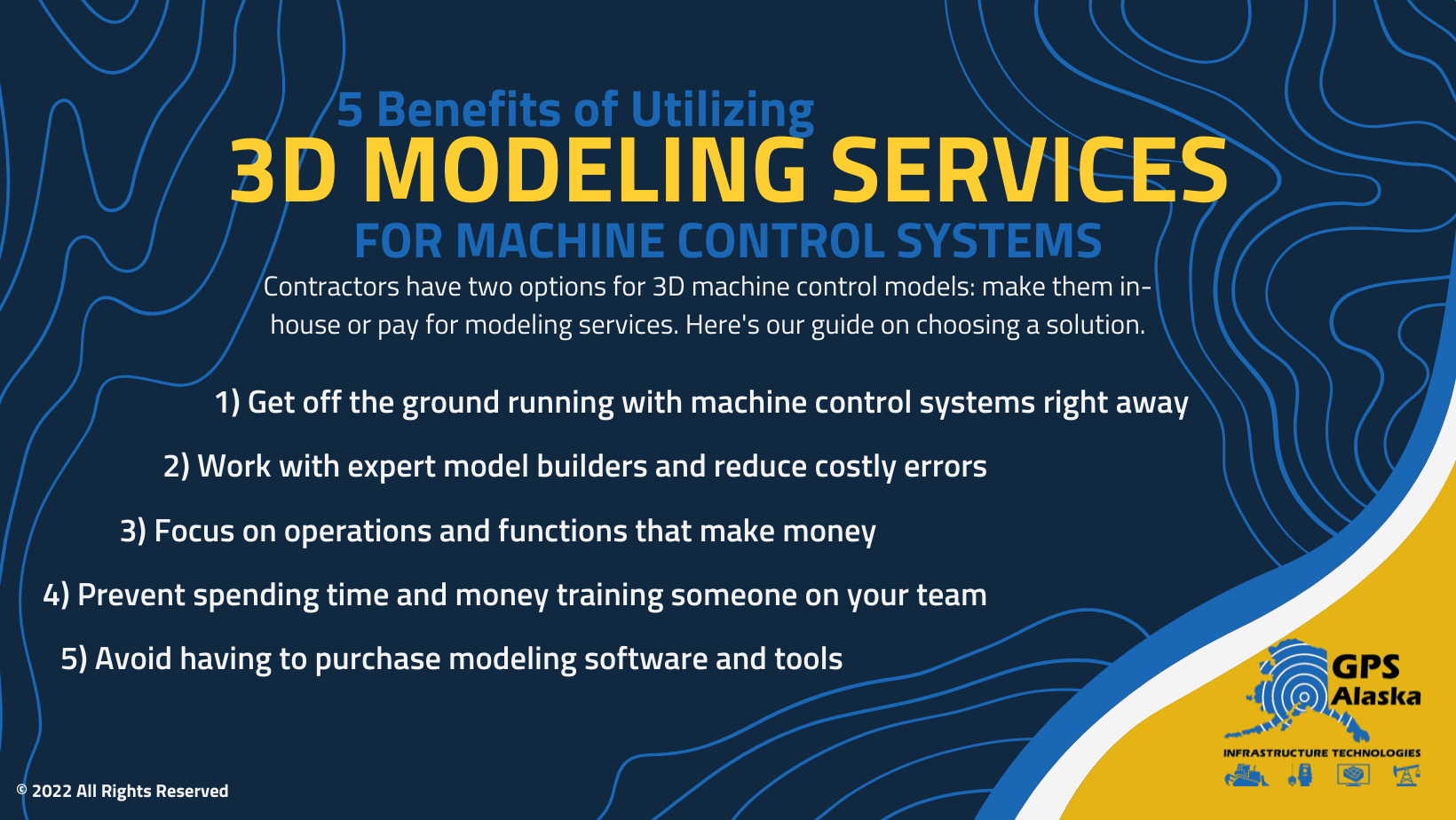

Trimble maker control systems offer a myriad of advantages to any person that makes use of earthwork machinery and, at EarthCalc, we can provide you with 3D declare your equipment control-enable tools. Not exactly sure if equipment control is worth the expense? Think about the complying with reasons you need to consider this choice.

Utilizing GPS lined up with your 3D style documents, these systems basically guarantee that you will certainly eliminate or position the proper quantity of material at the building site. On a lot of construction sites, rework is a typical and aggravating fact, but with Trimble device control, you can remove the need for rework.

The Facts About Sheroz Earthworks Uncovered

Usually, with Trimble maker control, you can remove excess tools at a specific task site. As an example, a work that might have called for making use of 3 or four pieces of excavating equipment now might require just 2 tools to accomplish the very same see this here job in much less time. This permits you to move your tools to an additional job website and handle numerous tasks at once.

Report this page